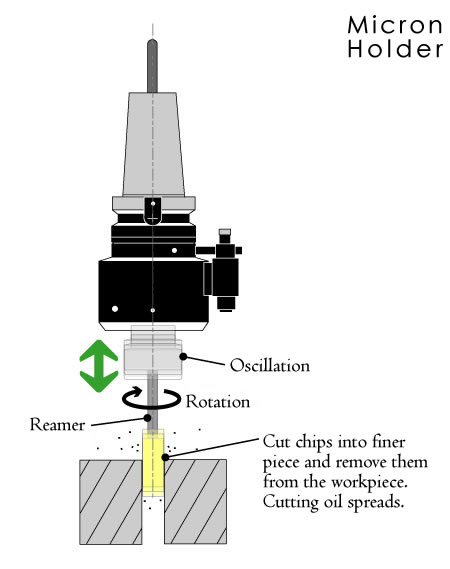

The “Micron Holder” transforms general purpose machines into honing machines.

|

This is an innovative holder that finely dices the chips, which can deteriorate the machining accuracy of the reaming process and damage the tool, and then expels the chips efficiently. The oscillation mechanism built into the holder dices the chips and promotes their expulsion, and also spreads the cutting oil throughout. A honing process that has micron-level tolerance, which was impossible to attain with conventional general purpose machines, is now possible with such machines, e.g., drilling machines. This innovative product makes it possible to use general purpose machines, as high-precision honing machines by fitting them with a holder that has a built-in oscillation mechanism. A honing process that has a micron-level tolerance, which is impossible to attain with conventional general purpose machines, is now attainable. It is suitable for a wide range of working materials that are difficult to polish, such as stainless steel, tempered steel, cast iron, cemented carbides, ceramics, and aluminum. Furthermore, the cutting oil can be either oil-based or water-based. The amplitude is adjustable between 0 and 1.0 mm. |